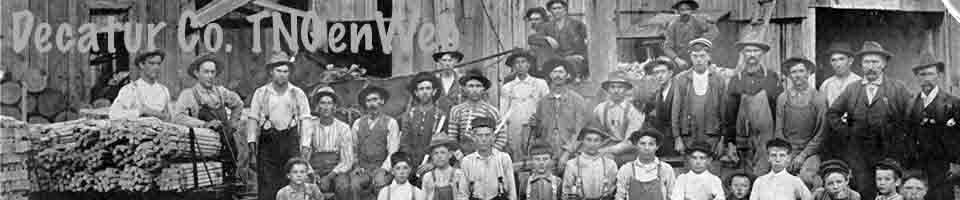

Salant & Salant Shirt Factory in Full Operation

from the collection of Brenda Kirk Fiddler

Salant & Salant Items Needed!

Please visit our new Salant & Salant section. Wouldn't it be great to preserve more of the history of the local Salant & Salant operations? We need your newspaper clippings, photographs and just good stories about the Salant and Salant factories that were formerly located in Lexington and Parsons. We need much more material for this section of this web site.

If you can contribute to this effort in any way, please contact me.

May 12, 1933, Lexington Progress

Where is the "croaker" who said that the shirt factory would never amount to anything and would not mean anything to Lexington and the county? If that person had been with the writer on a recent visit to, and through the factory, he'd change his tune, for with the busy atmosphere of flying fingers of skilled operators and the whirl of swiftly-moving machinery, it was a scene of animated activity from the first operation to the last.

Through the courtesy of the local manager, Mr. Shoemaker, an invitation was accepted to accompany him through the building and view the making of shirts, which was most interesting from start to finish. First, the material, 15,000 yards, is laid out on a cutting table (and there are two of these) 216 feet long. The pattern is drawn off on the top layer, and skilled operators, using electrically driven operators, [to be checked] cut through five or six inches of cloth and five hundred shirts are begun. From the cutting tables, the material goes to the machines, one group making the backs, one the fronts, where one operation turns down the pleat and does four rows of stitching at a time. Each separate part of the shirt is made by a different operator, then the parts are assembled and pass from one machine to another. One machine puts on collars, one cuffs, another pockets, buttons, etc., then the button holes which are cut and finished at one operation. Then the finished garment is turned over to the inspectors, fifteen of them, who rigorously examine them for the least possible flaw-and no raw seams, skipped stitches or any other imperfections are allowed to get by their watchful eye.

After being passed by the inspectors, the shirts are folded, a few deft manipulations of a folder-and the shirt is ready for the presses, and after three pressings, one with a 90 pound steam presser, then a dressing off with a hand, steam roller, then back to the hydraulic presser, and the finished garment, after going through 24 different operations, is boxed, ready for shipment.

There are now 150 employed to the factory, and while all are busy all the time, none are over-worked, they are not driven by "frenzied foremen," but they know the busier they are, the more they will make, so it's the thought of the pay-check that spurs them on to greater activity. And it isn't hard work either.

The collars have their edges pressed by a machine, then the collar-maker has only to put two pieces together and one operation of his machine has a collar neatly made with two rows of stitching around it. The same with the pockets, put on in a jiffy and everything is done by machinery-no edges to turn under, no hems to turn-the machines do it all. So it's a matter of nimble fingers, a little skill and swiftness, all of which comes with experience.

The building is comfortable, an ideal place in which to work, well-lighted on all sides, overhead, and with drop lights over the machines and the very latest methods of ventilation. There are fans to be installed soon and cold water to be supplied by electric refrigeration will be installed next week.

The building is also clean and sanitary and the operators are all well-dressed, good looking and from the county's best families. There are any number of graduates from our high school, and are to be complimented on their neatness and personal appearance. Neat operators mean neat work.

The present out-put of the factory is 2,700 shirts a day. There are half-million yards of materials in bales on the floor waiting to be cut and two tons of thread-great cones of 15,000 yards, each waiting to bind the many yards of goods into well-made garments.

This number of workers will be more than doubled when the new unit of machinery is installed, that will turn out 7,200 shirts daily, and will take 200 new operators to do the work-and most important of all, the work-most important of all, the payroll of over $2,400.00 monthly, [check figure] will be doubled.