By Gerald K. Moore

(© 2002 by Gerald K. Moore)

INTRODUCTION – A separate census of manufacturing was made at the same time as the census of population in 1860, and the census taker was told to inventory all industries producing more than $500/year of goods. The peak of prosperity for hamlet industries in most of the rural south occurred just before the Civil War. Later, more efficient power sources, mechanization, economies of scale, and assembly lines meant that more work could be done cheaper by people in large factories, and a migration of industry from hamlets to large cities began. Some hamlets ceased to exist. Other communities, especially those along railroads and major highways, became small towns.

Most hamlet industries in 1860 were small and served a local population. Typical were blacksmith shops, grist mills, lumber mills, tanneries, cotton gins, cooperages, furniture and wagon shops, shoemakers, saddle and harness shops, distilleries, etc. Most of these shops and mills in Wayne County were too small to be included in the census of manufacturing. Blacksmith, for example, was the most common occupation after farmer and laborer in the population census of 1860, but only one blacksmith shop and only one grist mill were included in the manufacturing census. Similarly, the transportation business (horse-drawn wagons for shipping goods to and from farms and industries) was omitted from this census.

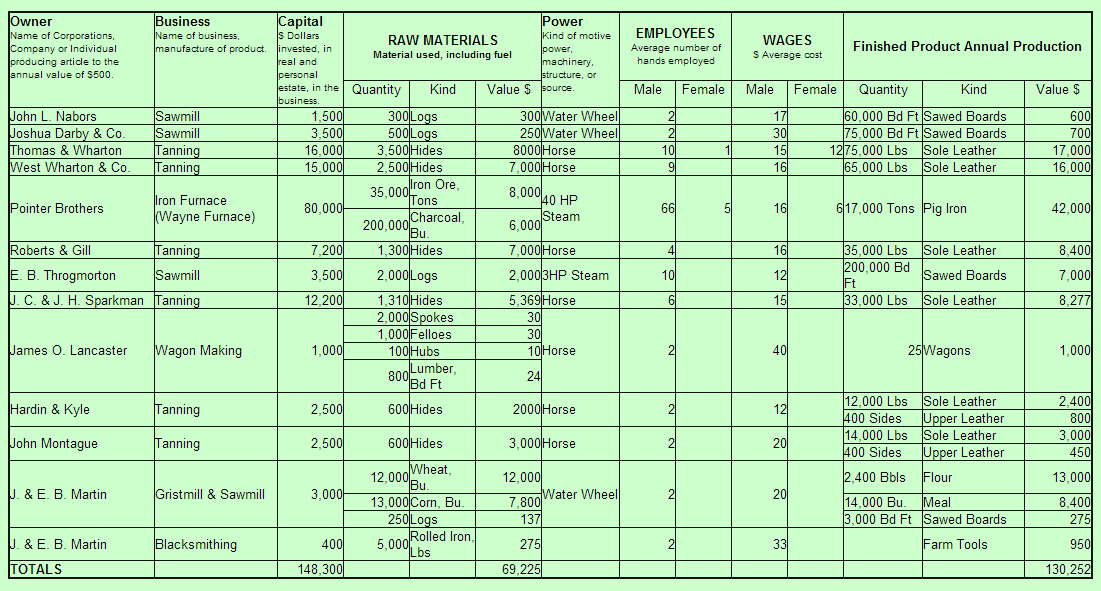

UNDERSTANDING THE DATA – The census taker was told to record the manufacturing data in 14 columns. Data for the few Wayne County industries were written on a single census page. Column numbers and explanations are as follows:

No, Label Explanation

1 Owner Name of corporation, company, or individual producing articles to the annual value of $500

2 Business Name of business, manufacture, or product

3 Capital $ Dollars invested, in real and personal estate, in the business

4-6 Raw Materials Material used, including fuel

4 Quantity

5 Kind

6 Value $

7 Power Kind of motive power, machinery, structure, or source

8-9 Employees Average number of hands employed

8 Male

9 Female

10-11 Wages $ Average cost

10 Male

11 Female

12-14 Finished Product Annual production

12 Quantity

13 Kind

14 Value $

Although not specified, it is almost certain that the amounts in cols. 10-11 represent the monthly pay of each worker. The low wage paid to female employees at the iron furnace probably shows that these women were part-time cooks for the iron workers (both free and slave).

ANALYSIS & INTERPRETATION – In some respects, the census of manufacturing for Wayne County in 1860 does not fit the usual picture wherein rural industries served only local needs. An iron furnace and several large tanneries depended upon imports, exports, or both. Wayne Furnace was located near several iron ore (limonite) mines and a bed of pure limestone (flux to lower the melting temperature). The surrounding forest was used to make charcoal for smelting the ore. A lot of trees were needed for the 200,000 Bu./year of charcoal used by the furnace. The wood from many other trees was used to roast the iron ore (to reduce its water content) before smelting and to fuel a 40 HP steam engine. The bellows or blowers that produced an air blast for Wayne Furnace were powered by water in earlier years, but the steam engine was apparently used for this purpose in 1860. Iron ore, charcoal, and limestone were carried to the furnace in horse-drawn wagons. The pig iron produced by the furnace was apparently not used in Wayne County. Elsewhere, molten metal from similar furnaces was used for cast-iron pipe, wood stoves, kettles, and frying pans. One history mentions that the iron from Wayne Furnace was shipped by steamboat from Clifton to Louisville and Cincinnati in 1860.

About 9,600 cattle hides were tanned in Wayne County in 1860, but, as described previously, there were only about 6,300 cattle in the county. Salted cattle hides were apparently shipped into Wayne County and tanned leather was shipped out. Unfortunately, the amount of tanbark (usually from red oaks and chestnut oaks) used by these industries was not included in the 1860 census.

The prices for raw materials in the census show the usual prices for these things in 1860. Logs worth $0.50-1.00 each were sawed to produce lumber worth about $9-35 per thousand board feet. One exception is the sawmill of J. and Edward B. Martin (line 12c), but it seems likely that this record is erroneous; the mill probably produced 30,000 bd. ft instead of 3,000 bd. ft of lumber in the previous year. The records also show that pig iron was worth about $2.50/ton, farm wagons cost about $40 each, sole leather cost about $0.20-0.25/lb., flour cost about $5.40/bbl. (3.3 Bu.), and cornmeal was worth about $0.60/Bu. Wages seem to have been $15-30/mo for men. One business reported a $40/mo wage , but it seems likely that this was for two employees. The only woman who was apparently working full time at an industry in Wayne County was paid $12/mo.

EVALUATION – If all significant expenses are shown in the 1860 census of manufacturing for Wayne County, raw materials costing $69,225 per year and labor costing $24,120 produced goods worth $130,252. The total profit made by the industries in the census was $36,907 per year on invested capital of $148,300. These industries thus made an average profit of 25% on the investments.

The census data show that the average factory wage in 1860 was about $20/mo. or $240/year compared with a median farm profit of about $150/year in Wayne County. Using an inflation factor of 175, as discussed previously, the equivalent factory wage today would be $42,000/year. Factory workers had to purchase food, fuel, clothing, and shelter (although room and board were provided by some employers.), but they didn’t have to make investments in land, animals, and equipment. Factory workers also didn’t have crop failures caused by bad weather or other risks associated with farming. By 1860, the lure of relatively high factory wages had already started a small migration from rural areas and hamlets to large cities; as wages slowly rose, this trend accelerated.